RED MUD

Bauxite Residue, a.k.a. Red Mud, is a byproduct residue of the alumina industry. More than 2.5 parts of red mud are produced for every part of aluminum. This means that over 150 million tonnes are produced each year, and left unused in giant pits.

This project explores the use of bauxite residue as a ceramic material, reimagines red mud as a resource rather than waste. Through a combination of scientific research and traditional craft techniques, a range of ceramic vessels was developed. The material’s high oxide content was also used to create a number of glazes. The work challenges perceptions of industrial byproducts, highlighting their untapped possibilities and potential beauty.

CONTEXT

Aluminium is not mined in its familiar metallic form. Rather surprisingly, its origins begin in a red stone, called bauxite. From this red ore, a white powder, ‘alumina’, is extracted, and then smelted into the metal we all know and interact with each day, including the very device you are reading this from.

This transformation of aluminium involves a global mechanism and system of extraction that operates at colossal scales and yet is nearly invisible to the everyday eye of its consumers. It is a system of extraction that exists to meet the demands of today. It is also vital to our future, given its recyclability, strength and lightweight nature. Often, this is at the cost of the locals from which it is mined. Ore is mined in countries like China, Brazil, Australia, Guinea and Jamaica, and shipped to refineries in the developed world, dissociating the final product from its material origins.

In the process of refining alumina, a red residue is left behind as a marker of these origins – a trace of the journey it has taken and a stark reminder of the costs, be it social, economic or environmental. This is red mud.

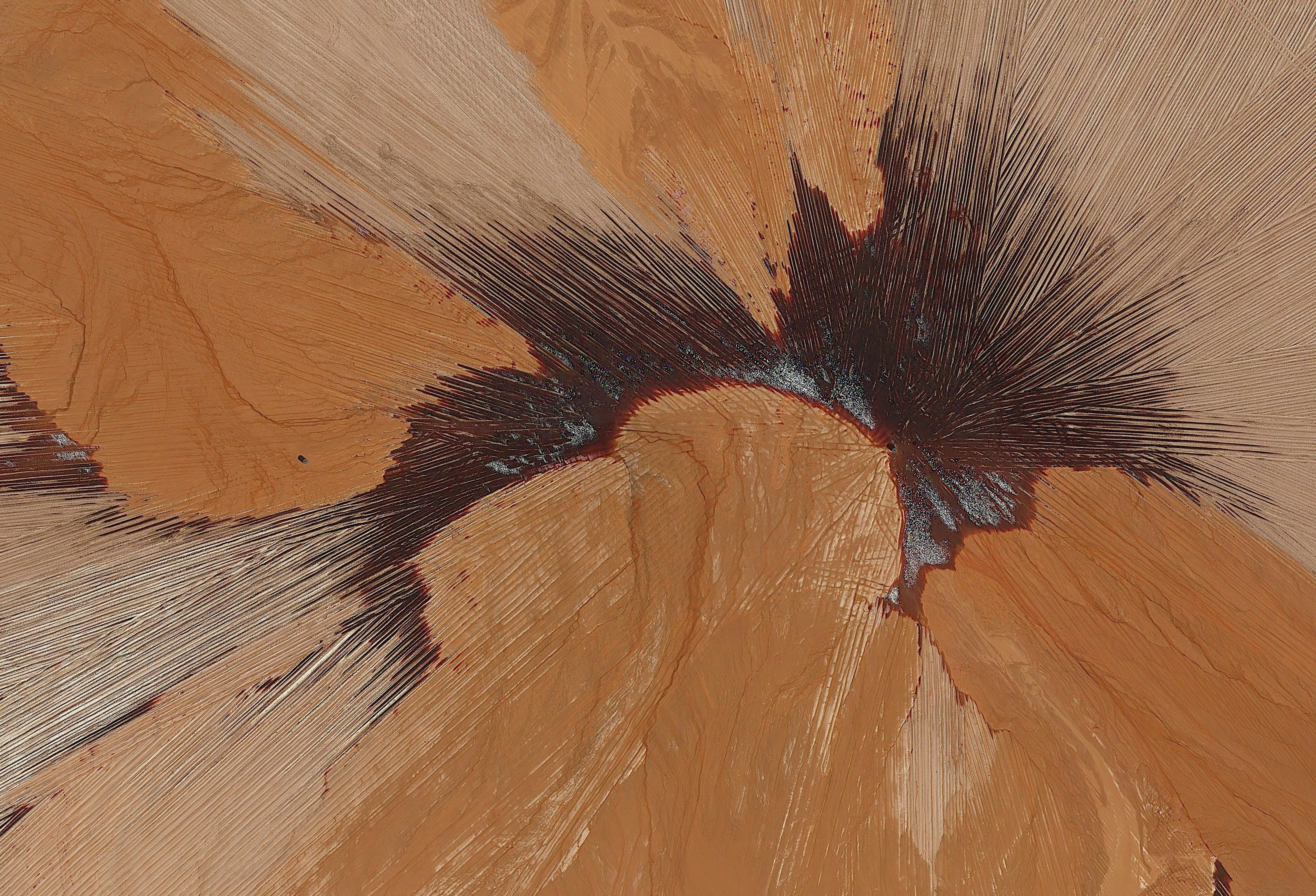

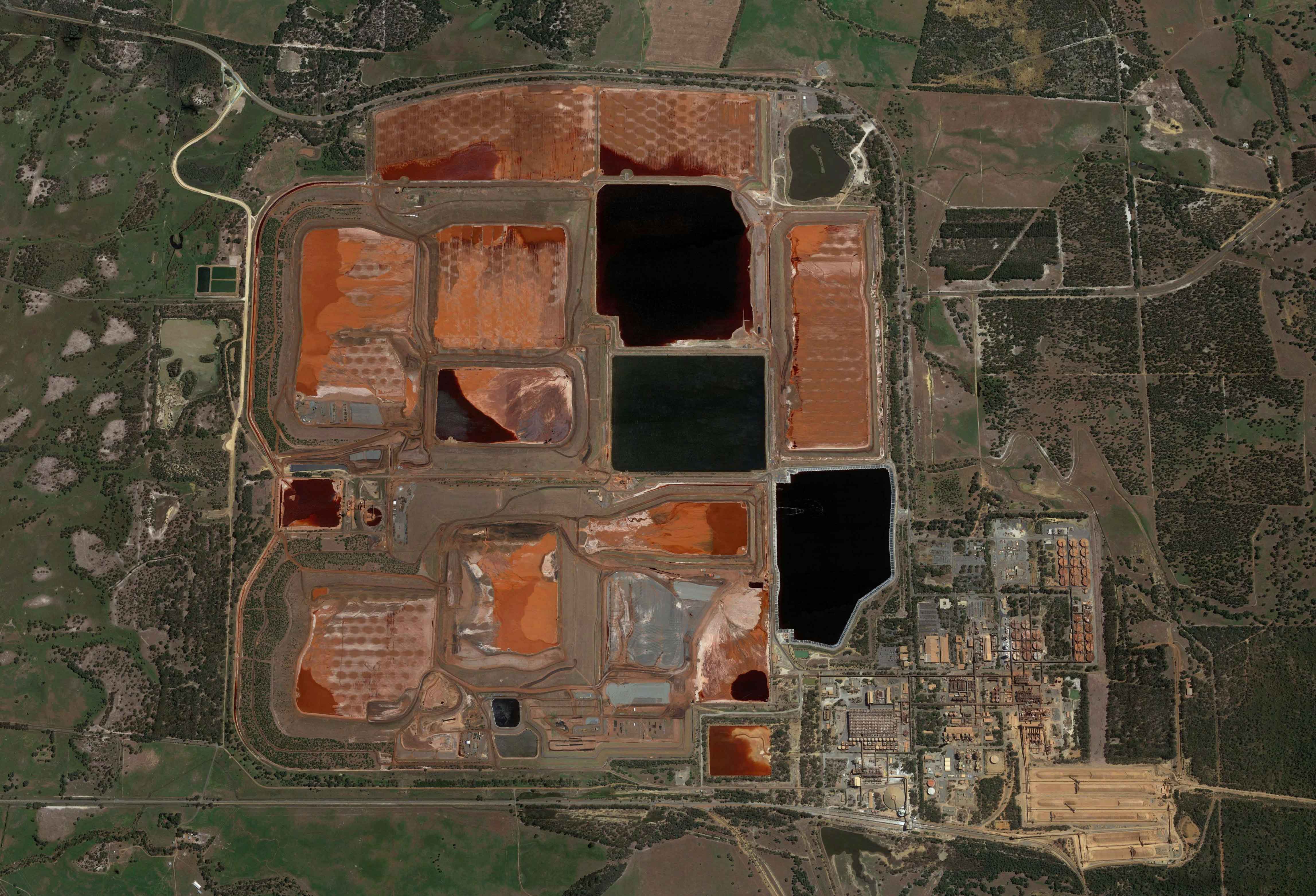

Red mud is presently left in hazardous landfills around the world, so large they can be seen from space. The global stockpile of red mud in these landfills exceeds 4 billion metric tonnes, growing by 150 million tonnes each year as our demands for aluminium continue to rise.

This transformation of aluminium involves a global mechanism and system of extraction that operates at colossal scales and yet is nearly invisible to the everyday eye of its consumers. It is a system of extraction that exists to meet the demands of today. It is also vital to our future, given its recyclability, strength and lightweight nature. Often, this is at the cost of the locals from which it is mined. Ore is mined in countries like China, Brazil, Australia, Guinea and Jamaica, and shipped to refineries in the developed world, dissociating the final product from its material origins.

In the process of refining alumina, a red residue is left behind as a marker of these origins – a trace of the journey it has taken and a stark reminder of the costs, be it social, economic or environmental. This is red mud.

Red mud is presently left in hazardous landfills around the world, so large they can be seen from space. The global stockpile of red mud in these landfills exceeds 4 billion metric tonnes, growing by 150 million tonnes each year as our demands for aluminium continue to rise.

While red mud has been extensively researched ever since the invention of the ‘Bayer Process’ (the process by which alumina is extracted), today only 3% is being used globally, despite multitudes of proven methods of valorization. The barriers to its reuse are manifold, but are heavily weighted by economics and legislation, both of which are intimately tied to public perception. In short, nobody wants a hazardous waste, and without this demand, there is little incentive or pressure to change.

Red mud has a bad rep, and for good reason. Depending on the source of the ore, red mud can contain heavy metals and radioactive elements. If the red mud is not properly treated, it can be highly alkaline. And even worse, if the waste site is incorrectly managed, it can lead to disasters such as the 2010 spill in Ajka, Hungary.

Red mud has a bad rep, and for good reason. Depending on the source of the ore, red mud can contain heavy metals and radioactive elements. If the red mud is not properly treated, it can be highly alkaline. And even worse, if the waste site is incorrectly managed, it can lead to disasters such as the 2010 spill in Ajka, Hungary.

But the problems faced by red mud are not immutable. Scientists have shown us that there are feasible solutions.

While it makes for an easy story to blame mining companies, they too are eagerly looking for solutions, so long as they are economically viable; in other words, if there is demand. Without a pull, there will be no push. So what is needed to shift the tide?

While it makes for an easy story to blame mining companies, they too are eagerly looking for solutions, so long as they are economically viable; in other words, if there is demand. Without a pull, there will be no push. So what is needed to shift the tide?

“Red mud has no narrative, other than that of waste. How can we show a different side to this stigmatized material? Can it be seen as refined, delicate, and even beautiful?”

Bricks have been made with red mud by scientists nearly five decades ago, and perhaps even earlier by grassroot efforts in regions like India. The composition of red mud is primarily common elements found in the ground: silica, iron, alumina, calcium. This , combined with the fine partical size, lends the material to being ‘sintered’, or fired into a ceramic body.

As much as bricks may seem reasonable, high-volume and low-value uses of red mud are difficult to implement in an economically viable way. This is mainly due to the high costs of waste processing, the new legislative hurdles, and the geographic location of most factories (these factories are usually remote, and transporting bricks is energy and cost intensive). How can we as designers contribute – changing the perceived value of this material?

Investigating the use of red mud in traditional ceramics, we aim to bring a new aesthetic to an otherwise unwanted resource. The fragility, finesse and natural touch of ceramics run in direct opposition to the brute and constructed nature of industry. It is precisely because of this that we made ceramics; to both draw attention to the industrial model behind our everyday materials, and to suggest an optimistic alternative.

As much as bricks may seem reasonable, high-volume and low-value uses of red mud are difficult to implement in an economically viable way. This is mainly due to the high costs of waste processing, the new legislative hurdles, and the geographic location of most factories (these factories are usually remote, and transporting bricks is energy and cost intensive). How can we as designers contribute – changing the perceived value of this material?

Investigating the use of red mud in traditional ceramics, we aim to bring a new aesthetic to an otherwise unwanted resource. The fragility, finesse and natural touch of ceramics run in direct opposition to the brute and constructed nature of industry. It is precisely because of this that we made ceramics; to both draw attention to the industrial model behind our everyday materials, and to suggest an optimistic alternative.

“The ‘Red Mud’ project represents a combination of traditional ceramics with scientific inquiry, a blend of craft and research, trial and error.”

Through traditional ceramics methods, we designed and produced a limited collection of tableware pieces, where both the body and the glaze are made from red mud. The ceramics method, combined with the right additions, neutralizes the red mud and renders it safe and useable.

The ‘Red Mud’ project began in our studies at the Royal College of Art, in London, in 2019. However, the investigation of this material continues to evolve, and we continue to work on new collections, private commissions, collaborations with architects, continued projects with scientists, and consultation for R&D teams of various mining companies.

The ‘Red Mud’ project began in our studies at the Royal College of Art, in London, in 2019. However, the investigation of this material continues to evolve, and we continue to work on new collections, private commissions, collaborations with architects, continued projects with scientists, and consultation for R&D teams of various mining companies.

PROCESS